helical high feed end mills

Designed for high feed applications Helicals fully stocked offering of High Feed End Mills take advantage of chip thinning with a specifically engineered end profile for optimal tool engagement and reduced cutting forces. I was going to helical interpolate this right now I have an 1 14 90 deg.

The Secret Mechanics Of High Feed End Mills In The Loupe

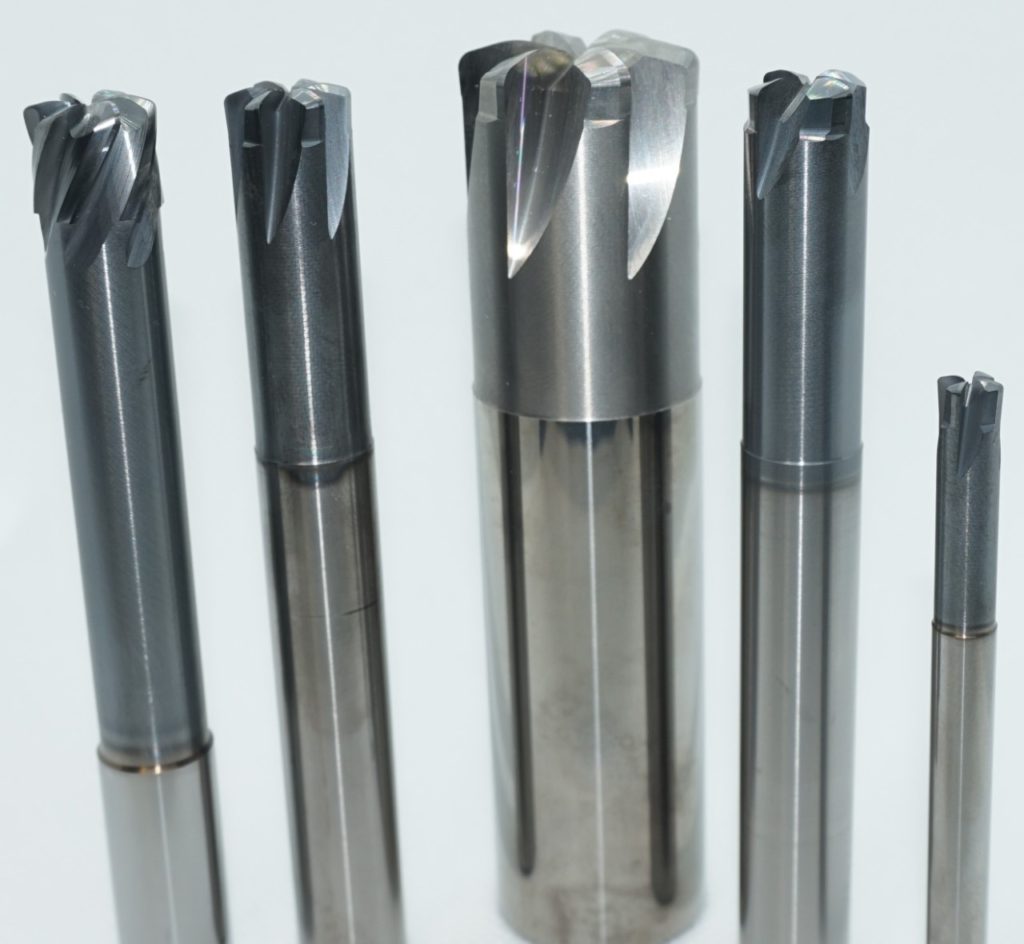

High-Feed Milling Mechanism First utilized in the die and mold industry high-feed milling is a machining method that pairs shallow depth of cut DOC with high feed rate up to 20 mm per tooth.

. Shop Emuge EF Drills Ti Taps and Emuge TiNox End Mills from Tool-Kribs online catalog or contact us to for expert advice and personal customer service. They should also shorten your run time too. The depth is 1 12.

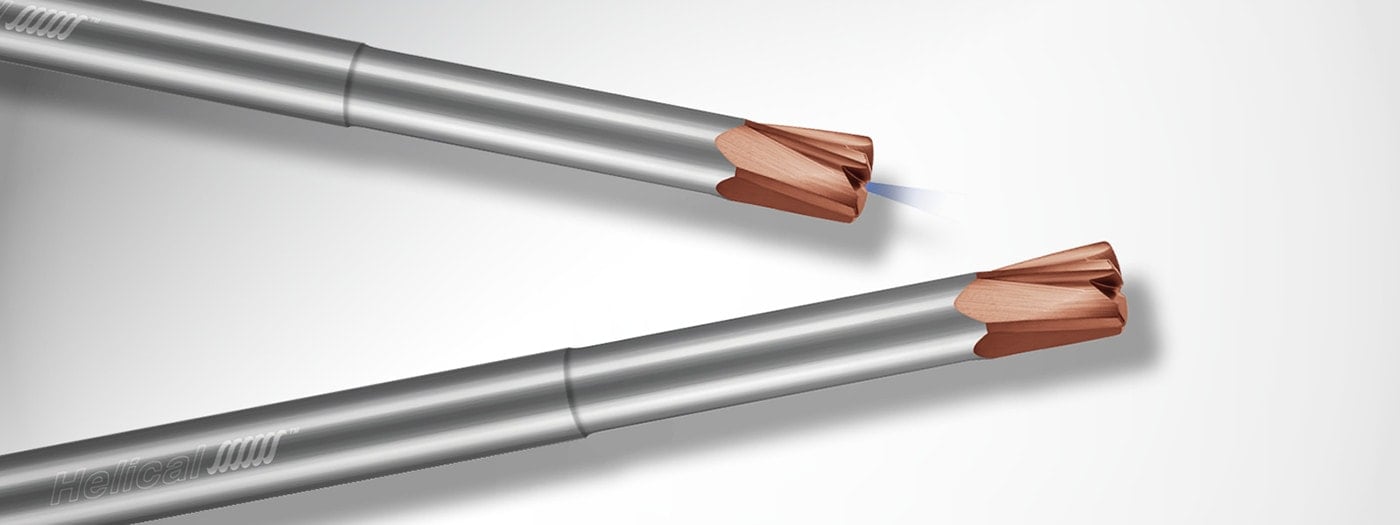

Straight-through coolant hole option for superior chip evacuation and heat management at the cutting edge. High Feed End Mills - Steels up to 45 Rc - Variable Pitch - Reduced Neck The specifically engineered end profile of this fully stocked offering of High Feed End Mills reduces cutting forces while its reduced neck geometry provides maximum strength in. 31 rows High Feed End Mills - Steels up to 45 Rc - Variable Pitch - Reduced Neck The.

Curvature of the Bottom Edge of High Feed End Mills. 15 to 4 Wall Thickness 028 to 237 Speeds Variable Up to 18 FPM 3 x 134 76mm x 3mm YODER SOMENOR W20P. Helical Solutions High Feed End Mills provide many opportunities for machinists and feature a special end profile to increase machining efficienciesA High Feed End Mill is a High Efficiency Milling HEM style tool with specialized end geometry that utilizes chip thinning allowing for drastically increased feed rates in certain applications.

Tool-Krib can supply you with premiere. All Helical High Feed End Mills feature Tplus coating which provides optimal tool life in a variety of metals up to 45 Rc. MAP is our go-to solution for High Efficiency Milling and has exponentially decreased our run times as well as increased our tooling life.

The Kennametal 1-12 Cut Diam 006 Max Depth 1-14 Shank Diam Cylindrical Shank Indexable Helical High-Feed End Mill Takes 3 Inserts Screw Holding Method WP06X4. The milling technique for these tools allows for drastically increased feed rates to maximize chip thickness and keep. We cut slots all day long in 4140.

Figure 6 shows a side by side comparison. The Kennametal 1 Cut Diam 004 Max Depth 1 Shank Diam Cylindrical Shank Indexable Helical High-Feed End Mill Takes 4 Inserts Screw Holding Method WP0302. The Kennametal 1-14 Cut Diam 0059 Max Depth 1-14 Shank Diam Cylindrical Shank Indexable Helical High-Feed End Mill Takes 3 Inserts Screw Holding Method WOEJ090512.

WELDED STAINLESS TUBE MILLS Stk 111201 2 Tube Mill Lines With A Shared Spare Set of Rafted Stands Rafter Model RT -3000S-12 Laser Welded Mill With Bright Annealing Material Previously Run 304 316 301 294C 2205 OD. 090 High-Speed Cutting Mills. Does anyone have experience with Dapra or another recommendation Thank You.

Home Helical Solutions High Feed End Mills High Feed End Mills. 17 rows High Feed End Mills - Steels up to 45 Rc - Variable Pitch - Reduced Neck The. Endmill w inserts I was looking at videos of mills made by Dapra with round inserts they call it the toroid mill they say it is supposed to reduce cycle time.

Exposure may cause cancer andor reproductive harm. I would use a 58 WhisperKut from Dura-Mill. Variable pitch geometry results in higher quality final parts by decreasing chatter and harmonics during machining.

Using MasterCam dynamic milling and whisperkuts end mills. Check out the speeds and feeds chart. While standard end mills.

This product may contain metals andor chemicals that are included in the State of Californias latest Prop 65 warnings. The specifically engineered end profile of this table of Helical Solutions Feed Mills results in optimal tool engagement and. High Performance Modular Solid Carbide End Mills DUO-λOCK General Purpose End Mills.

High Feed End Mills - Steels up to 45 Rc - Variable Pitch - Reduced Neck. This combination maximizes the amount of metal being removed from a part and increases the number of finished parts in a given time. Our sales team is available Monday Friday from 830AM-6PM and can be reached at 973-808-4550 or click here to email our sales team for a quote.

Dura-Mills WhisperKut Speed and Feed High Performance End. Use the light roughing as described at the bottom of the chart. Machining Advisor Pro paired with Helical End Mills is the Holy Grail of End Mill Performance.

As metalworking experts in the milling industry we distribute helical end mills to micro small medium and large businesses across North America. With a range of helical end mills from leading manufacturers including Niagara Cutter Walter-Prototyp Seco and more MSC Industrial Supply makes it easy to find the right part for your needs. For example the large partial radius of the Helical Solutions High Feed End Mill bottom cutting edge will leave a smaller scallop when compared to a ball end mill programmed with the same tool path.

Helical Solutions High Feed End Mills provide many opportunities for machinists and feature a special end profile to increase machining efficienciesA High Feed End Mill is a High Efficiency Milling HEM style tool with specialized end geometry that utilizes chip thinning allowing for drastically increased feed rates in certain applications. While standard end mills have square. The smaller the radius of curvature the larger the height of the scallop.

Helical Carbide End Mill 3 4 5fl 0 188 Radius Hssp 12485 Amazon Com Industrial Scientific

Helical Solutions Products All Industrial Tool Supply

5 Things To Know About Helical S High Feed End Mills In The Loupe

5 Things To Know About Helical S High Feed End Mills In The Loupe

4 6 Flute High Feed End Mills Epic Tool

Roughing End Mills For Steels Results Page 1 Sl Fusco

The Secret Mechanics Of High Feed End Mills In The Loupe

Zrn Coated 3 16 Dia 3 Flute High Helix Carbide Rougher X 625 Loc Maritool